- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

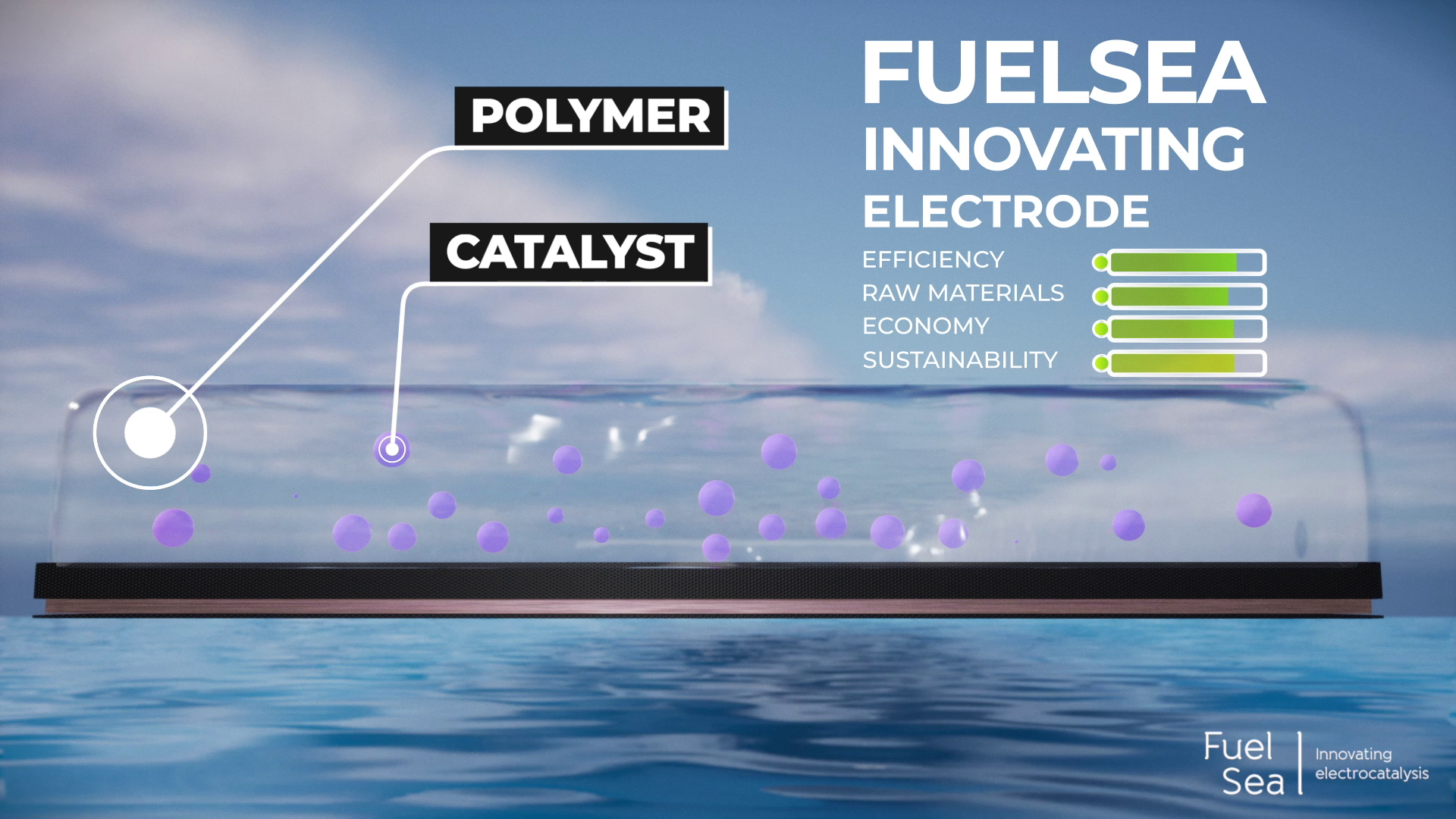

The FuelSea project seeks to revolutionize the market for water disinfection by salt electrolysis by proposing a new electrode design.

Currently the main issue limiting the deployment of water disinfection by electrolysis is centred around the economic and environmental cost of the salt electrolysers. This process consists to generate an in situ solution of hypochlorous acid (biocidal agent) by passing an electric current through a solution of salty water, by means of electrodes. These electrodes have been based for 30 years on a unique model called DSA® consisting of a titanium plate covered with ruthenium, iridium and platinum catalysts. These 4 elements have been classified as so-called strategic materials by the European Union, as their economic cost is highly subject to recent geopolitical uncertainties (imports from Russia, China, South Africa) and may represent a risk with regard to the sovereignty of the technologies associated with them.

The FUELSEA project supported by SATT Linksium and Labex ARCANE develop a manufacturing process of composite materials for electrode coating. This bio-inspired coating contains sub-nanometre-sized metal particles with active surfaces and mass activities superior to existing electrodes on the market. In addition, this technology allows the diversification of the nature of the catalysts by using abundant transition metals and allows their recycling.

Benefits :

- Saving strategic resources

- Reduction of the environmental footprint

- Improved catalytic performance through nanostructuring of catalysts

- Recyclability and biodegradability of electrodes at the end of their life.

Project dates

Start : May 2022

End : May 2023

Project team

Project leader : Marie-Noëlle Collomb

Post-doctoral fellow : Baptiste Dautreppe, Damien Mouchel-dit-Leguerrier, Richard Barré

Patents

In progress, Under study by the National Patent Institute

Rewards

Award winner i-PhD 2022

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn